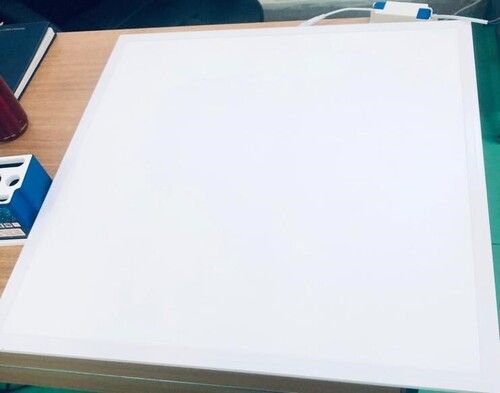

2X2 LED Light BASE PANEL

800 INR/Piece

Product Details:

- Color Temperature 6500K/3000K/4000K Kelvin (K)

- Shape SQUARE

- Product Type COMMERCIAL LED PANEL

- Power Factor >0.95

- Input Voltage 220-240V Volt (V)

- Working Temperature 25-60 Celsius (oC)

- Lamp Power 36W Watt (W)

- Click to View more

X

2X2 LED Light BASE PANEL Price And Quantity

- 10 Piece

- 800 INR/Piece

2X2 LED Light BASE PANEL Product Specifications

- COMMERCIAL LED PANEL

- 2X2

- SQUARE

- >0.95

- 220-240V Volt (V)

- 36W Watt (W)

- 6500K

- COMMERCIAL

- 25-60 Celsius (oC)

- 6500K/3000K/4000K Kelvin (K)

2X2 LED Light BASE PANEL Trade Information

- 50000 Piece Per Month

- 10 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

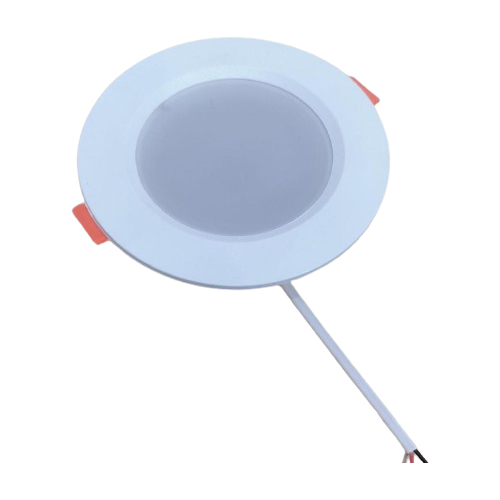

Other Products in 'LED Light' category

|

MILKY TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send SMS

Send SMS